❬ BACK TO HOME

PUMPS

WATER PUMPS

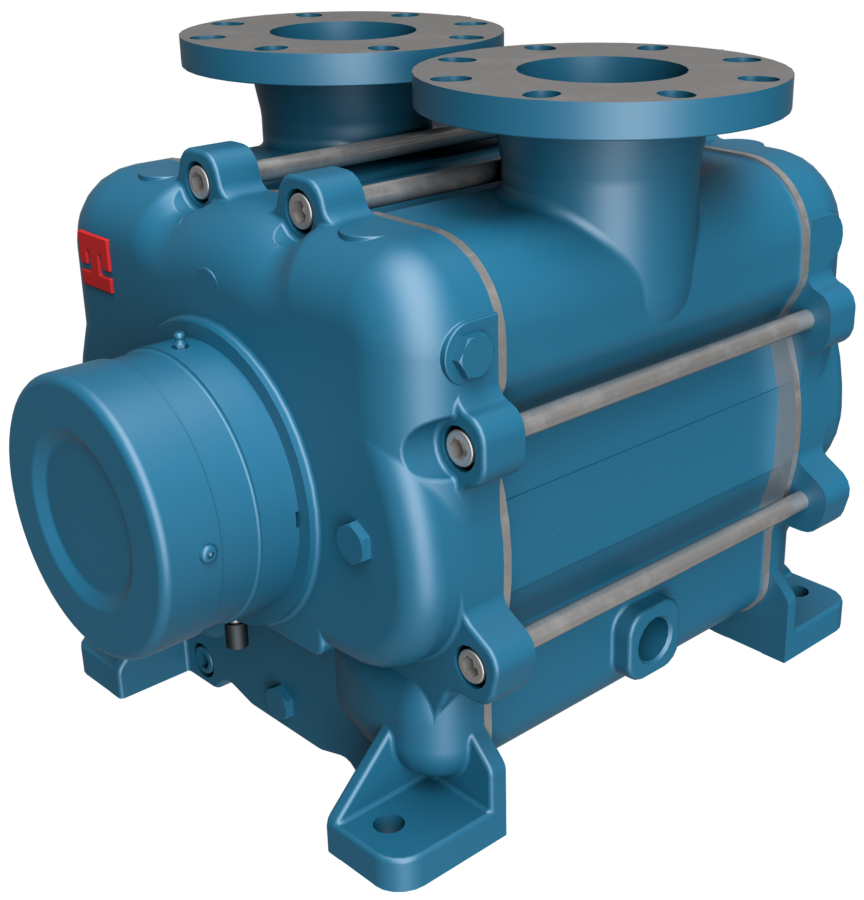

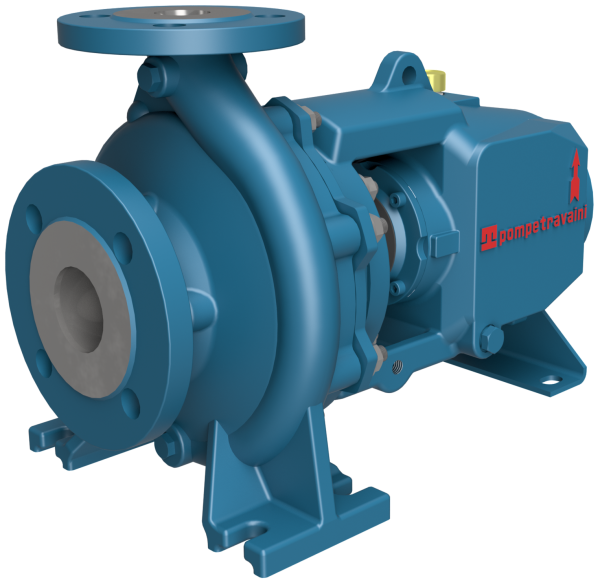

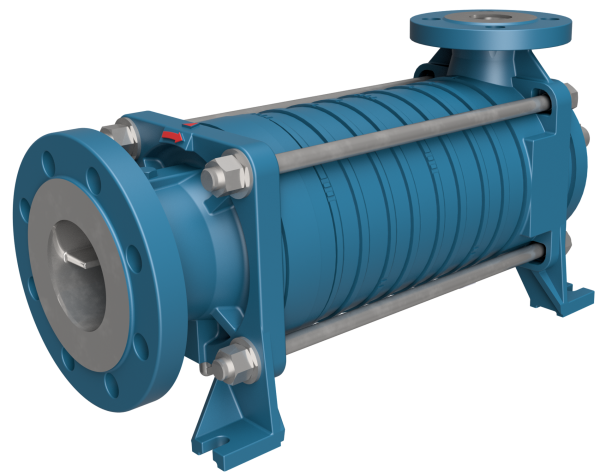

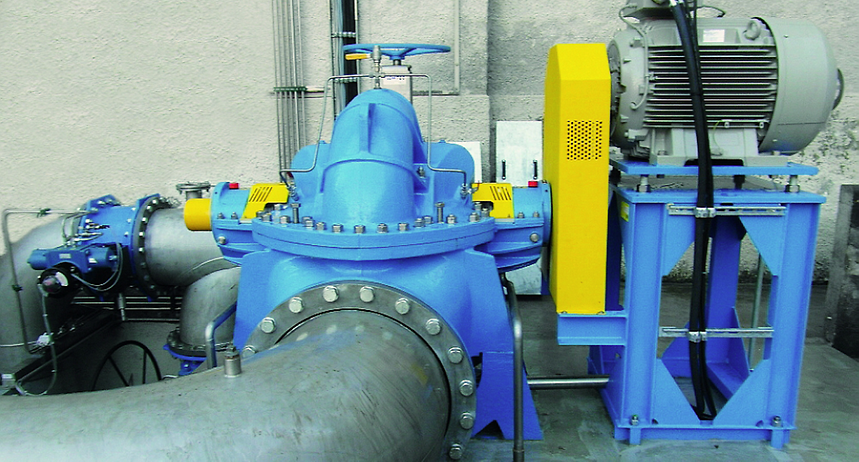

ANDRITZ develops and manufactures standard and customized centrifugal pumps such as end-suction, split case, high-pressure and numerous other pumps for a wide range of different applications and industries.

- Highest energy efficiencies

- Lower life-cycle-costs

- High-standard pump engineering

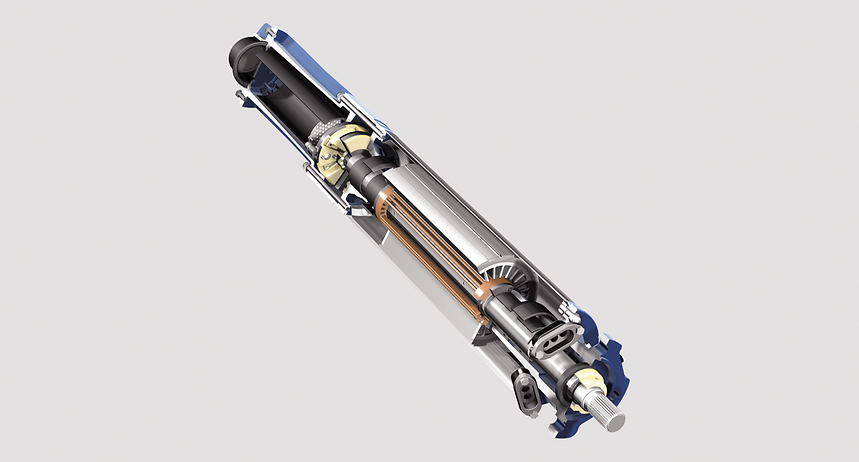

ANDRITZ develops and manufactures submersible motors for various fields of application in water supply, mining and offshore. Equipped with a special cooling technology (MCT) and an interior permanent motor technology (IPM), ANDRITZ submersible motors achieve impressive performance values, efficiencies, and cost savings.

Their rewindable winding makes ANDRITZ submersible motors from the SM series the ideal drivers for submersible deep well pumps, bottom intake pumps, seawater lift pumps, and for subsea machinery. Thus, they can be used for water supply and in the offshore as well as the mining industry. They are designed as water- filled and water-cooled three-phase asynchronous motors with squirrel-cage rotors with a mechanical shaft seal. Depending on the field of operation, ANDRITZ submersible motors from the SM series can be made of cast iron, bronze or stainless steel and can be installed vertically and horizontally.

ANDRITZ SM motor series - low-voltage motors:

ANDRITZ SM motor series - high-voltage motors:

Product benefits:

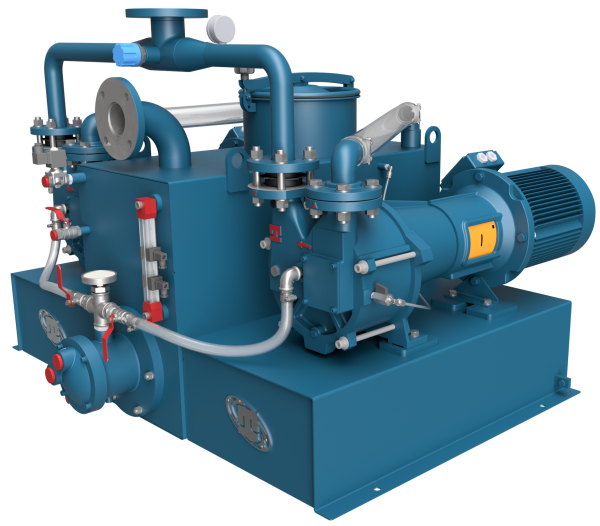

By operating in backward mode, the pump becomes a mini-turbine that can generate a very healthy ROI by recovering and generating electrical power. ANDRITZ pump- turbines are an economical alternative, compared to the cost of buying and operating a conventional turbine. They operate, for example, as recovery turbines in pulp and paper mills, in small hydropower plants, and supply energy to mountain refuges and forest lodges. Thereby, the transport various media ranging from drinking water, residual and waste water as well as pulp suspensions.